Φύλλο χάλυβα πυριτίου: το βασικό συστατικό για την αποτελεσματική λειτουργία των σύγχρονων μετασχηματιστών

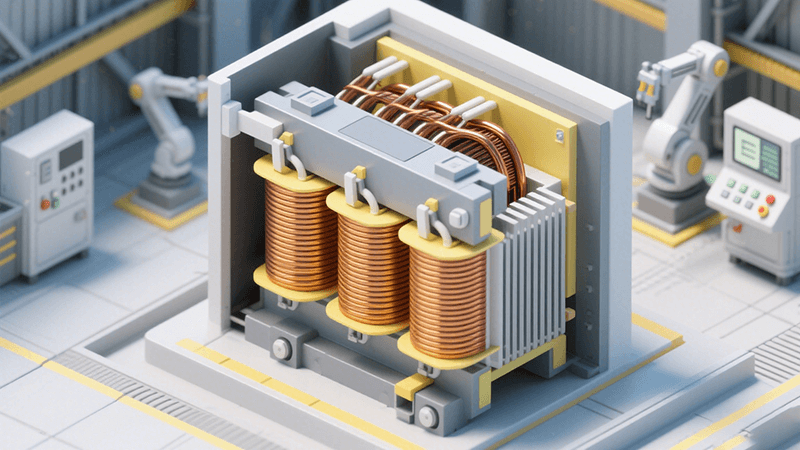

Have you ever wondered why transformers—from massive power plants to household appliances—rely so heavily on silicon steel sheets? These ultra-thin, layered silicon-rich steel sheets serve as the core component of transformer cores, directly determining the equipment’s energy efficiency, operational performance, and lifespan. This article delves into the indispensable core logic of silicon steel laminated transformers, their underlying operating principles, and why our company consistently advocates prioritizing silicon steel in modern transformer design.

I. The Science Behind Silicon Steel Transformer Laminations

Περιεχόμενα

- 1 I. The Science Behind Silicon Steel Transformer Laminations

- 2 II. Manufacturing Process of Silicon Steel Sheets: Dual Control of Precision and Performance

- 3 III. Core Advantages of Silicon Steel Transformer Laminations

- 4 IV. Grade and Specification Variations of Silicon Steel Sheets

- 5 V. Stringent Quality Control: Ensuring Excellence in Every Laminate

- 6 VI. Environmental and Compliance Advantages

- 7 VII. Diverse Applications of Silicon Steel Sheets

- 8 VIII. Cost and Benefits: Short-Term Investment, Long-Term Returns

- 9 IX. How to Select a Quality Silicon Steel Sheet Supplier?

- 10 X. Conclusion: Silicon Steel Sheets—The “Power Heart” of Modern Transformers

1. The Crucial Role of Magnetism and Silicon

The exceptional performance of silicon steel laminated transformers stems from their unique magnetic properties. By incorporating silicon into the iron matrix, manufacturers significantly reduce hysteresis losses—the energy dissipated when magnetic domains rearrange during repeated magnetization cycles. This property is critical for transformer efficiency: lower hysteresis losses mean less electrical energy is converted into useless heat, allowing more power to be delivered precisely to the target load. Our company leverages this scientific principle to develop transformers with exceptional energy retention capabilities.

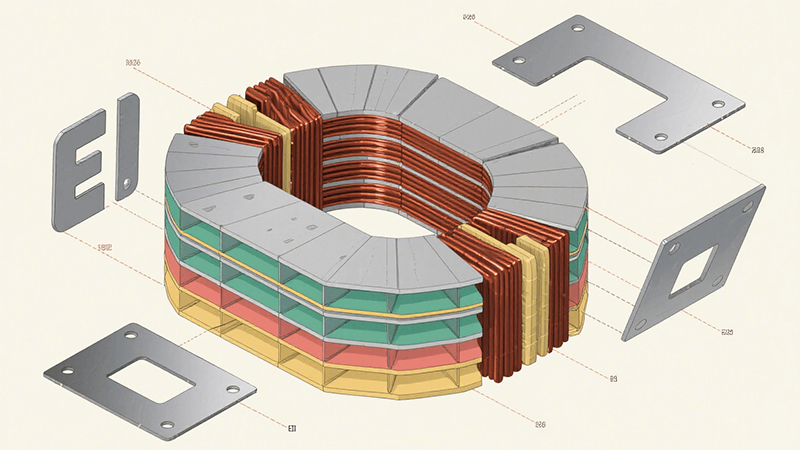

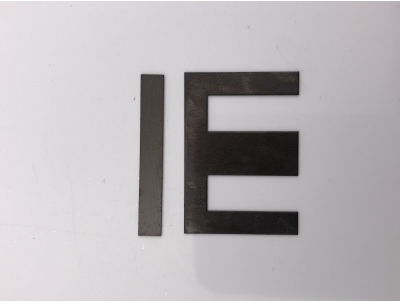

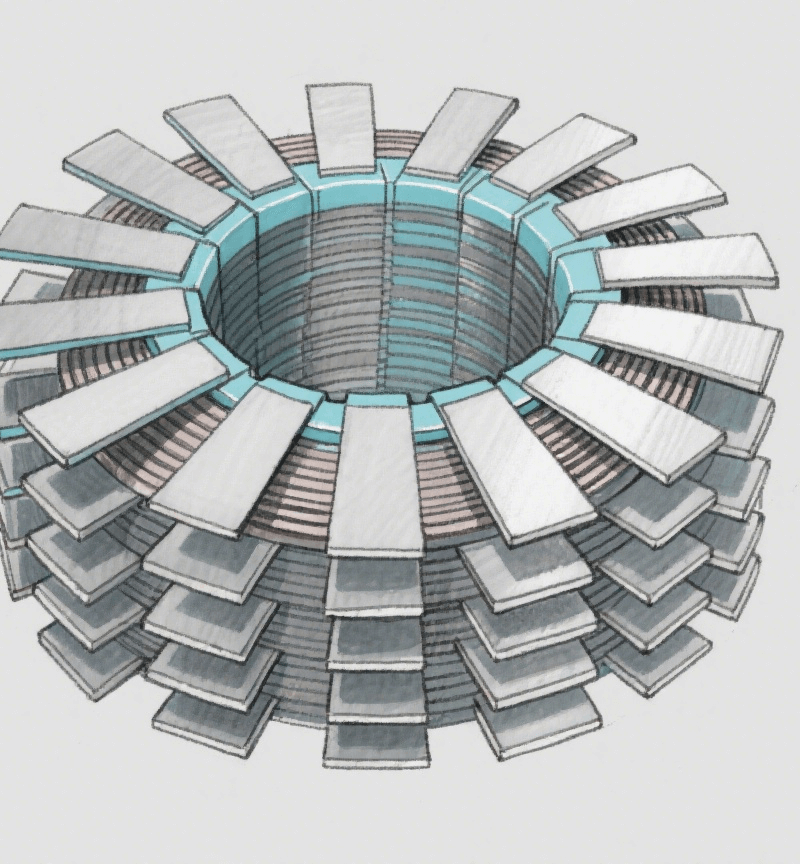

2. Layered Design: The Ingenuity Behind Minimizing Eddy Current Losses

Another key design feature of silicon steel transformer laminations lies in their layered stacking structure. The core isn’t a solid steel plate but consists of multiple ultra-thin silicon steel sheets, each coated with an insulating layer. This design effectively suppresses eddy current losses: due to the insulating barrier, eddy currents can only circulate within a single thin laminate, preventing the formation of large currents throughout the entire core. The thinner the laminate, the shorter the eddy current path, resulting in lower losses and further enhancing the overall efficiency of the transformer.

II. Manufacturing Process of Silicon Steel Sheets: Dual Control of Precision and Performance

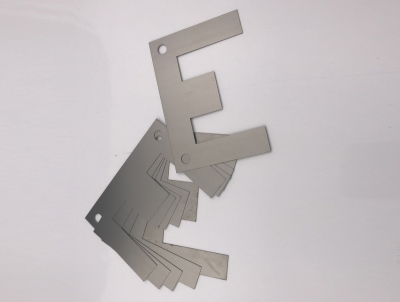

1. From Casting to Rolling: Crafting High-Specification Base Sheets

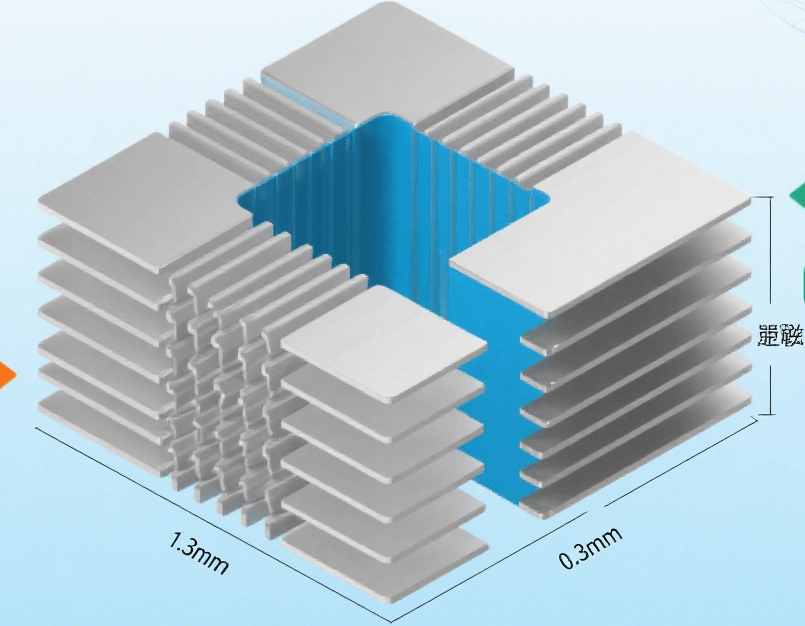

Production of high-quality silicon steel transformer laminations begins with strict control over the casting process. Precise management of the melting process ensures uniform distribution of silicon elements within the steel, preventing localized composition variations that could compromise magnetic properties. Subsequently, the steel billet is rolled to a precise thickness (typically just a fraction of a millimeter) before undergoing annealing. This process involves heating and cooling according to a specific temperature curve to optimize the internal magnetic domain structure while eliminating internal stresses generated during rolling. Our company employs industry-leading annealing technology to ensure the produced silicon steel sheets maintain stable and reliable performance even under high electrical load conditions.

2. Insulating Coating: Safeguarding Performance and Extending Lifespan

Following annealing, silicon steel sheets receive a sprayed insulating coating, commonly composed of epoxy resin or phosphate. This coating serves dual purposes: it isolates the steel from air and moisture, preventing rust and oxidation to preserve long-term magnetic properties, while also providing electrical isolation between adjacent laminations to further suppress eddy current generation. Our company employs precise coating control processes to ensure uniform coating thickness and pinhole-free surfaces on every sheet. This significantly enhances the structural stability and service life of the iron core.

III. Core Advantages of Silicon Steel Transformer Laminations

1. Significant Improvement in Energy Efficiency

The combination of “high silicon content + thin-layer structure” in silicon steel laminations simultaneously reduces both hysteresis loss and eddy current loss. The direct effect of this dual reduction is lower operating temperatures, reduced daily energy consumption, and substantially enhanced long-term operational economics. Based on our company’s actual test data, silicon steel laminations achieve up to 30% greater energy savings compared to cores made from traditional electrical steel.

2. Enhanced Performance Stability and Reliability

Reduced iron losses not only conserve energy but also directly improve the transformer’s overall performance. Lower heat generation slows the aging rate of insulation materials, extending the service life of both the core and the entire equipment. Furthermore, silicon steel sheet transformers maintain stable magnetic properties even under significant load fluctuations, ensuring reliable power supply across diverse applications including industrial production, commercial offices, and residential settings.

3. Compact and lightweight design

Superior magnetic properties mean that silicon steel sheet cores require less material for the same rated power. This enables transformers to achieve more compact structures and lighter weights, making them ideal for modern portable electrical equipment or space-constrained installations (e.g., small substations, building distribution rooms).

IV. Grade and Specification Variations of Silicon Steel Sheets

Φύλλο χάλυβα πυριτίουs are categorized into multiple grades based on silicon content (maximum approximately 3.5%) and manufacturing precision, with each grade suited for different applications:

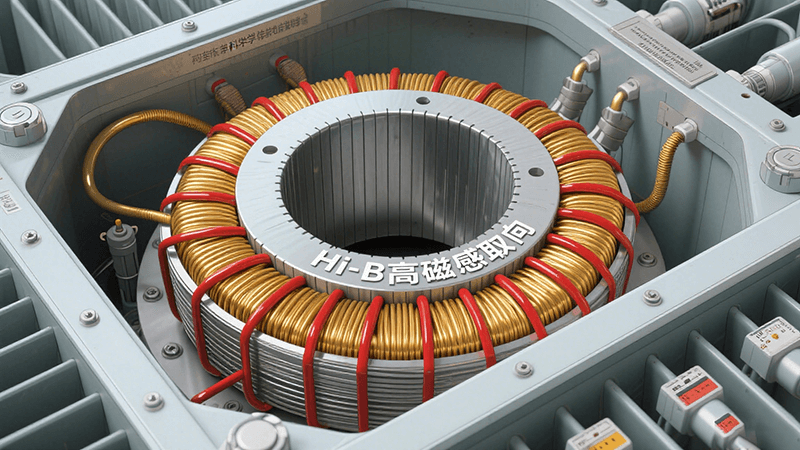

High-permeability grain-oriented (Hi-B) silicon steel sheets: Offer optimal magnetic properties and minimal core losses, primarily used in large power transformers to meet high-efficiency demands for long-distance transmission.

Non-oriented electrical steel sheets: Provide balanced magnetic properties at a relatively moderate cost, widely applied in general-purpose and distribution transformers for medium-to-low voltage power distribution scenarios.

Our company offers a full range of laminated silicon steel transformer products, customizable to specific requirements—whether for large power transformers rated up to 35 MVA or compact substation equipment as small as 5 kVA, we provide tailored silicon steel sheet solutions.

V. Stringent Quality Control: Ensuring Excellence in Every Laminate

The stable operation of transformers relies on the consistency of silicon steel sheet quality. To this end, our company has established a comprehensive quality assurance system, with core control points including:

Chemical Analysis: Verifying the uniformity of silicon content and other alloying elements through methods such as spectral detection to ensure material compliance.

Magnetic Testing: Using specialized equipment to inspect key parameters like core loss and magnetic permeability of each silicon steel sheet, screening out non-conforming products.

Dimensional Inspection: Utilizing high-precision measuring instruments to examine laminate thickness, flatness, and external dimensions, ensuring compliance with assembly requirements;

Surface Inspection: Employing visual inspection and coating adhesion tests to confirm insulation coatings are free of scratches, pinholes, and other defects.

These measures guarantee each batch of silicon steel laminations meets stringent electrical performance standards and mechanical durability requirements.

VI. Environmental and Compliance Advantages

Efficient energy utilization not only reduces operational costs but also significantly contributes to environmental protection. Transformers employing optimized silicon steel sheets minimize power losses, indirectly reducing greenhouse gas emissions from thermal power generation. Furthermore, our silicon steel sheets strictly comply with global environmental standards like RoHS and regional regulations worldwide, ensuring environmental friendliness throughout the product lifecycle. This supports the development of clean, safe power infrastructure.

VII. Diverse Applications of Silicon Steel Sheets

1. Power Transformer Sector

Large-capacity power transformers (e.g., backbone grid equipment) demand exceptionally high core efficiency. With their outstanding low-loss properties, silicon steel sheets have become the preferred core material for utility-grade transformers used in long-distance transmission and grid interconnection.

2. Distribution and Industrial Transformers

In medium- and low-voltage transformers deployed across industrial sites and urban distribution grids, silicon steel sheets significantly enhance equipment thermal management and operational efficiency. This reduces shutdowns caused by overheating and lowers enterprises’ maintenance and operational costs.

3. Specialized and Custom Transformers

Specialized equipment like rectifier transformers, electric furnace transformers, and traction transformers require tailored magnetization profiles and load curves. Our company provides customized silicon steel sheet solutions tailored to these specialized requirements, ensuring stable operation under specific working conditions.

VIII. Cost and Benefits: Short-Term Investment, Long-Term Returns

Compared to standard electrical steel, silicon steel laminations typically incur a 20%-40% higher initial procurement cost. However, from a long-term operational perspective, this investment delivers significant economic advantages:

Lower energy losses directly reduce electricity expenses;

Reduced operating temperatures lower cooling system energy consumption and maintenance costs;

Extended equipment lifespan delays the substantial investment required for replacing transformers.

For an industrial transformer, the cost premium of silicon steel laminations can be recouped through electricity savings within just a few months of normal operation.

IX. How to Select a Quality Silicon Steel Sheet Supplier?

When choosing a reliable supplier of laminated silicon steel sheets for transformers, focus on these core competencies:

Formulation and Process Advantages: Does the supplier possess proprietary silicon steel composition formulations enabling precise control of silicon content and alloy ratios?

Coating Technology Capabilities: Is the internal coating system stable, ensuring consistent and repeatable insulation performance?

Testing Capabilities: Does the supplier utilize advanced equipment like single-sheet testers and laminated stack testers to comprehensively validate product performance?

Customization Services: Can the supplier flexibly adjust laminate dimensions, thickness, and edge profiles according to customer requirements?

Our company possesses mature capabilities across all these areas, providing customers with end-to-end assurance from product to service.

X. Conclusion: Silicon Steel Sheets—The “Power Heart” of Modern Transformers

Silicon steel laminations are far from ordinary metal components; they form the core lifeline enabling modern transformers to operate efficiently. Their outstanding advantages in energy efficiency, magnetic properties, thermal stability, and compact structure make them an indispensable key material in the power equipment sector. Our company remains committed to innovation in silicon steel sheet R&D and quality control, empowering global customers to build more efficient, reliable, and environmentally friendly power systems through our high-quality products.

Final Recommendations

If you are designing, refurbishing, or procuring transformers, we recommend focusing on the following issues to ensure selection of suitable silicon steel laminations:

What grade of silicon steel laminations will the transformer use? Does it match the equipment’s power rating and application scenario?

What is the quality of the insulation coating on the laminations? Can it effectively suppress eddy current losses?

Do the magnetic properties (e.g., permeability, iron loss values) meet the operational requirements of the target equipment?

Has the product passed relevant industry testing and certifications (e.g., RoHS, electrical performance standards)?

Choosing a partner with our proven expertise and reputation ensures you receive silicon steel laminations that meet performance standards and deliver reliable quality, backed by long-term technical support and service guarantees.