Analyse complète de la technologie des stratifiés du cœur du réacteur

As a core component of electrical equipment, the performance of transformers directly impacts the operational effectiveness of the entire system. Among the key technologies determining transformer performance, operational efficiency, and service life is the laminated core of reactors. This article comprehensively analyzes Comprehensive analysis of reactor core laminate technology, delving into their core advantages, material selection, manufacturing processes, and practical application scenarios.

I. Definition and Core Value of Cœurs laminés de réacteurs

Contents

- 1 I. Definition and Core Value of Reactor Laminated Cores

- 2 II. Construction Process of Reactor Core Laminations

- 3 III. Technical Advantages of Laminated Core Technology for Reactors

- 4 IV. Application Scenarios for Reactor Core Laminations

- 5 V. Comparison with Solid Core Designs

- 6 VI. Case Study: Practical Application in Distribution Transformers

- 7 VII. Sustainability and Energy Efficiency

- 8 VIII. Future Innovation Directions for Reactor Core Laminations

- 9 IX. Conclusion: The Core Value of Reactor Core Lamination

- 10 X. Frequently Asked Questions (FAQ)

(1) What Are Laminated Core Sheets for Reactors?

Simply put, laminated core sheets for reactors are a technical process that uses thin insulated steel sheets (rather than solid steel blocks) to construct the reactor’s magnetic core. This unique structural design overcomes the limitations of traditional solid cores, laying the foundation for enhanced reactor performance.

(2) Why Are Laminated Core Sheets for Reactors Critical?

Significantly Reduces Eddy Current Losses: By layering thin steel sheets ranging from 0.15 mm to 0.35 mm in thickness, laminated cores effectively interrupt the flow paths of eddy currents. These circulating currents within solid cores cause substantial energy waste, a problem precisely addressed by the layered design.

Significantly enhances operational efficiency: Reduced energy loss in core components translates to improved overall equipment efficiency, aligning closely with Electrical Appliance Co., Ltd.’s core objective of pursuing high-efficiency production.

Effectively minimizes heat generation: By maximally suppressing eddy currents, the laminated core process reduces heat production during operation. This not only lowers the risk of equipment overheating but also extends its overall service life.

Enhanced Magnetic Performance: Laminated cores exhibit higher magnetic permeability, significantly boosting a transformer’s power handling capacity.

II. Construction Process of Reactor Core Laminations

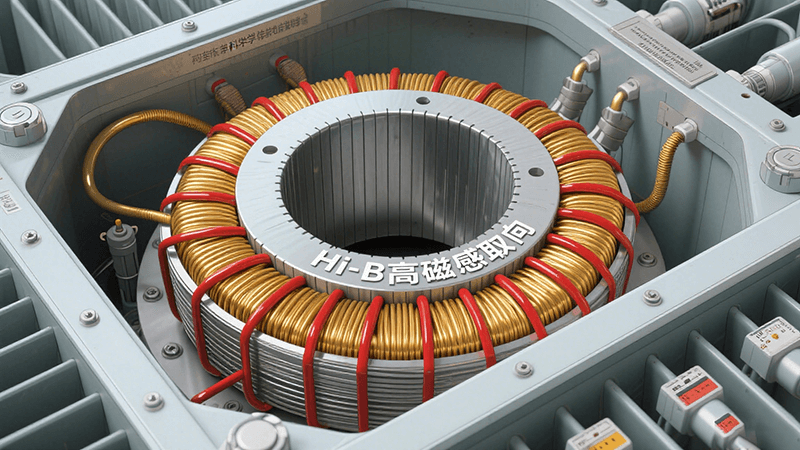

(1) Material Selection: Premium Electrical Steel as the Foundation

High-quality electrical steel is essential for reactor core laminations. Selection should prioritize three key dimensions:

Silicon Content: Typically incorporating approximately 3% silicon to minimize energy loss.

Grain Orientation: Grain-oriented steel exhibits superior magnetic properties in specific directions, making it ideal for transformer cores.

Coating Type: Insulating coatings like inorganic films prevent short circuits between laminations, ensuring stable core operation.

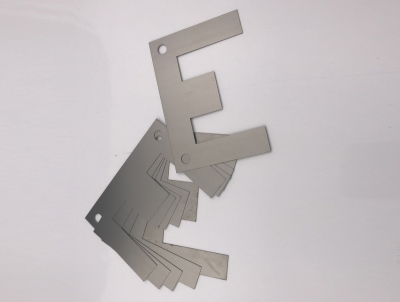

(2) Precision Cutting and Stamping: Ensuring Structural Accuracy

Advanced stamping equipment enables high-precision cutting of steel strips, ensuring seamless assembly of each laminate. The precision of the stamping process directly impacts two critical metrics:

Laminate Adhesion: Imperfections along laminate edges directly hinder stacking density, compromising core performance.

Stacking Accuracy: Precisely shaped laminates enable uniform stacking, maximizing magnetic performance.

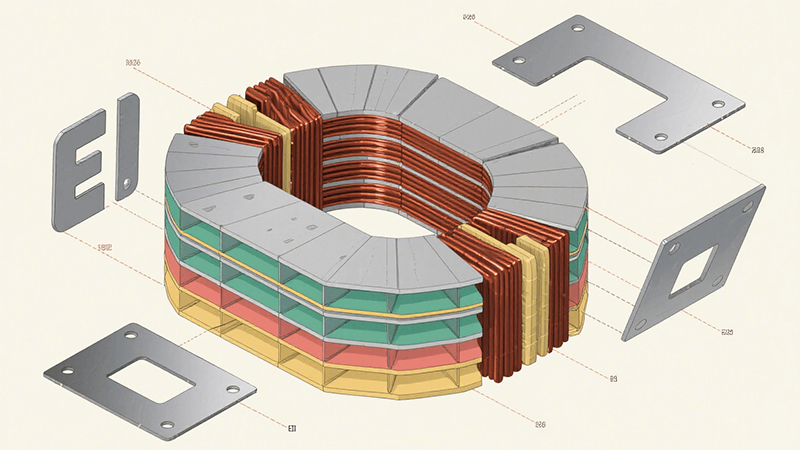

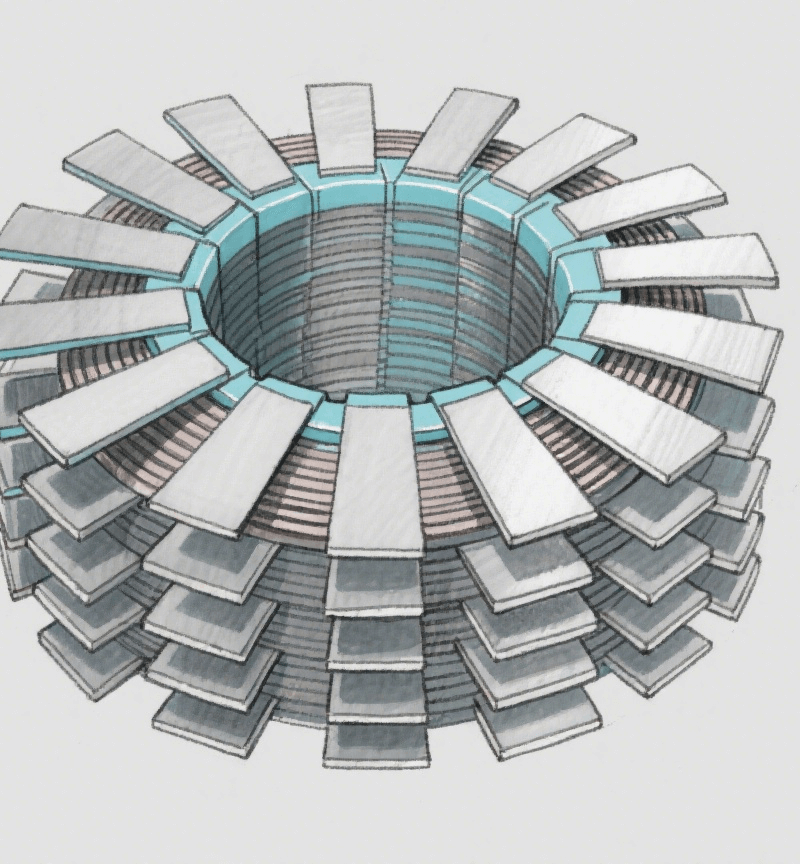

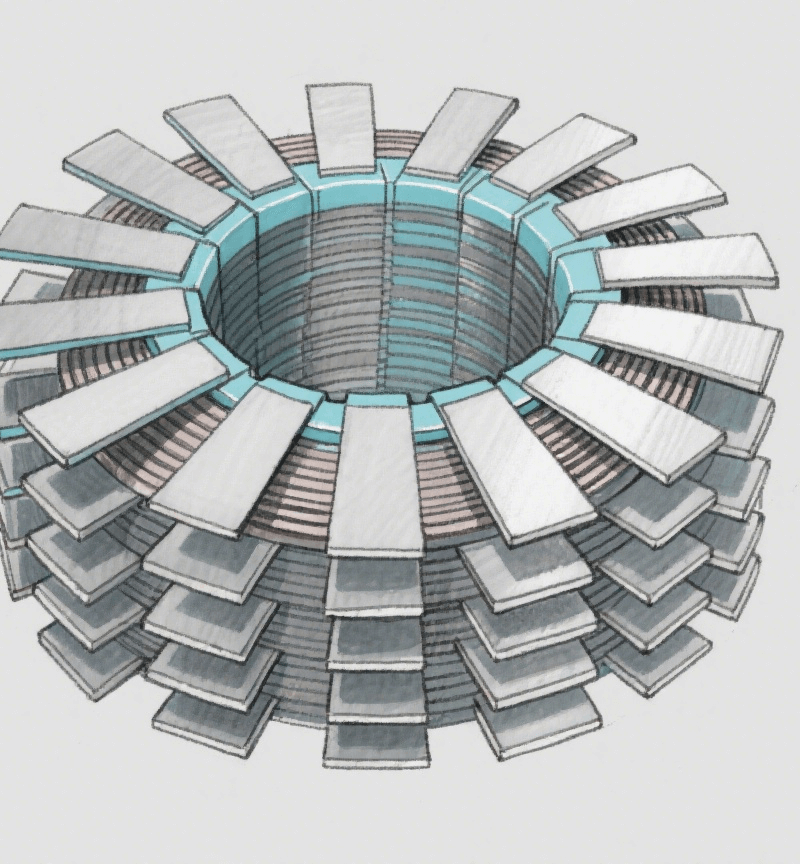

(III) Stacking and Bonding: Ensuring Structural Stability

Following stamping, laminations undergo meticulous stacking and bonding. Structurally, reactor cores primarily employ two lamination configurations:

Butt Laminations: Edges remain flush for simplified construction.

Interlocked Laminations: Utilize staggered joints to further enhance operational efficiency.

Bonding methods include welding or mechanical clamping. Advanced designs may employ vacuum pressure bonding to eliminate air gaps between laminations and improve stacking efficiency.

(IV) Annealing Treatment: Restoring and Optimizing Magnetic Properties

After stacking, the laminated core undergoes annealing. This process primarily relieves internal stresses generated during stamping and cutting. Through heat treatment, it restores the crystalline structure of electrical steel, ultimately enhancing its magnetic performance.

III. Technical Advantages of Laminated Core Technology for Reactors

(1) Minimized Eddy Currents: Reduced Losses, Enhanced Performance

Thin insulated steel layers disrupt eddy current loops within the core, mitigating inefficiencies caused by eddy currents. Specifically, this achieves:

Significantly reduced core losses, minimizing energy waste.

Enhanced equipment operational performance and reduced overall energy consumption.

(2) Reduced Hysteresis Losses: Optimized Magnetic Domains for Stable Operation

The heat treatment during laminate manufacturing refines the crystal structure and optimizes magnetic domain distribution, delivering two key benefits:

Minimized hysteresis losses, further lowering energy consumption.

Smoother magnetic behavior and more stable operation under alternating magnetic fields.

(3) Optimized Heat Dissipation: Ensuring High-Load Operation

By suppressing eddy currents to reduce heat generation, the laminated core exhibits outstanding thermal performance:

Improves overall equipment cooling efficiency, preventing localized overheating.

Effectively lowers equipment temperature even under high-load operating conditions.

(4) Compact Design: Adapting to Space-Constrained Scenarios

A higher stacking coefficient minimizes wasted volume within the core, enabling smaller, lighter reactor designs—a critical advantage for space-limited electrical equipment.

IV. Application Scenarios for Reactor Core Laminations

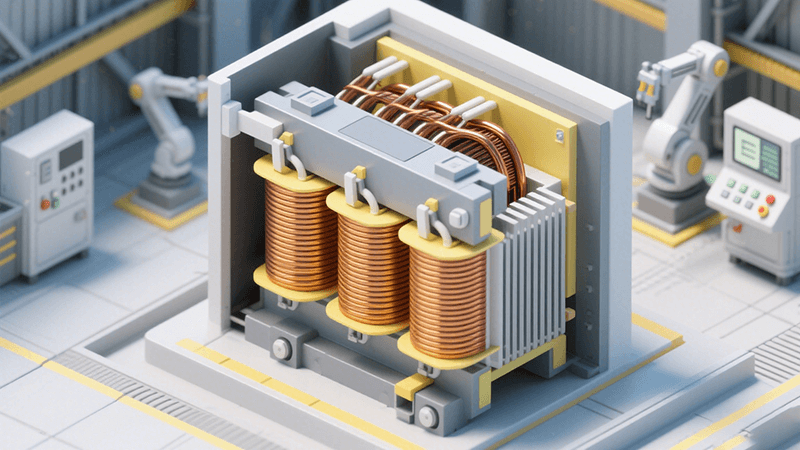

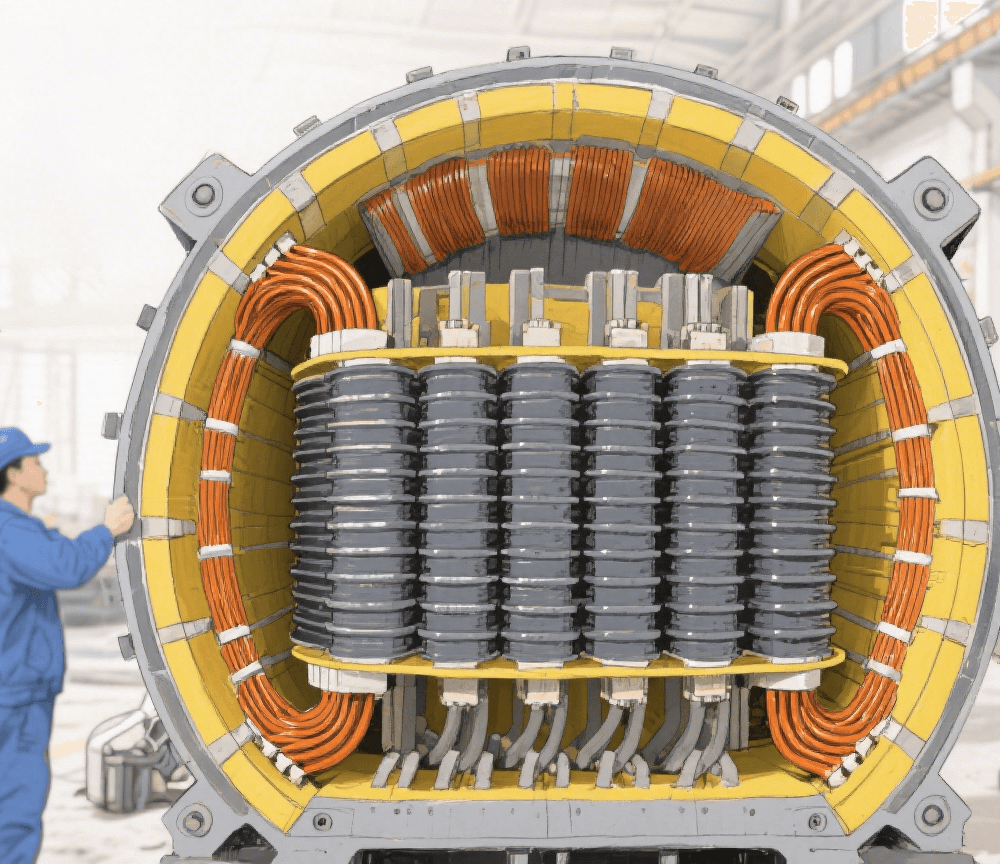

Leveraging its outstanding technical advantages, reactor core lamination technology is widely adopted across various electrical products. As a trusted manufacturer, Electrical Appliances Co., Ltd. integrates this technology into the following core products:

Power Transformers: Covering distribution and grid transformers, these are core devices for power transmission.

Chokes and Filters: Stabilize current flow and filter noise to ensure circuit stability.

Rectifiers and Inverters: Enable electrical energy conversion to adapt to diverse power requirements.

High-Voltage Reactors and Smoothing Reactors: Applied in power electronics to enhance operational stability in high-voltage environments.

Across all these applications, laminated core technology significantly improves equipment reliability, capacity, and thermal performance, ensuring sustained optimal operation.

V. Comparison with Solid Core Designs

Although solid core designs remain in use due to their lower cost and simpler structure, laminated core reactors offer more pronounced advantages:

Eddy Current Losses: Laminated designs reduce eddy current losses by approximately 50%–70%, significantly outperforming solid cores.

Permeability: Laminated cores exhibit higher permeability and superior magnetic performance.

Heat Generation: The laminated design markedly reduces heat production, lowering equipment overheating risks.

VI. Case Study: Practical Application in Distribution Transformers

A recently launched distribution transformer incorporates advanced laminated core technology for reactors, with the following specifications and performance characteristics:

Steel Grade: GO electrical steel, 0.23 mm thick, with inorganic surface coating.

Annealing Process: Multi-stage annealing at 750°C effectively reduces internal core stresses.

Stacking Coefficient: Achieves a high stacking coefficient of 0.965 through interlocking joint design.

Performance Metrics: Standby losses reduced by 40%, core compactness improved by 20%.

Final results demonstrate enhanced stability under load, superior temperature control, and significantly extended service life, fully embodying the value of exceptional design.

VII. Sustainability and Energy Efficiency

“Green manufacturing” has become a core development direction in the modern electrical appliance industry. Laminated core technology for reactors offers significant advantages in sustainability and energy efficiency:

Minimizes iron loss to reduce energy consumption.

Reduces greenhouse gas emissions throughout the transformer’s lifecycle, meeting environmental standards.

Supports the use of recycled steel and laminated core remanufacturing, promoting resource circulation.

Electrical Appliances Co., Ltd.’s commitment to sustainability extends beyond selecting fully recyclable materials. Through a lean production system centered on laminated core design, the company achieves dual enhancements in environmental performance and operational efficiency.

VIII. Future Innovation Directions for Reactor Core Laminations

To further overcome technical bottlenecks, Electrical Co., Ltd. is continuously investing in R&D to explore new possibilities in reactor core laminate technology, focusing on:

Experimenting with nanocrystalline and amorphous steel materials to further reduce energy losses.

Developing advanced bonding techniques such as epoxy resin pressing and laser welding to optimize stacking efficiency.

Designing customized laminate shapes tailored to the magnetic field distribution requirements of specialized reactors.

Moving forward, the company will persistently drive technological innovation with the goal of enhancing the efficiency and compactness of power transformers.

IX. Conclusion: The Core Value of Reactor Core Lamination

The significant impact of reactor core lamination on equipment performance stems from its unique structural design and process advantages:

The laminated structure interrupts eddy current paths, reducing energy dissipation as heat.

Steel subjected to precision annealing reduces hysteresis losses and optimizes magnetic properties.

Higher stacking density enables core miniaturization and weight reduction.

These advantages ultimately translate into enhanced efficiency, reliability, and sustainability, making power equipment better aligned with modern industrial demands.

For Electrical Appliance Co., Ltd., laminated cores for reactors represent not merely a manufacturing technique but a cornerstone of engineering excellence. By refining the design and processing of each laminate, the company delivers high-quality transformers and reactors that meet today’s multifaceted demands for efficiency, reliability, and environmental sustainability.

X. Frequently Asked Questions (FAQ)

Q: What is the typical thickness range for laminated reactor cores?

A: Typically between 0.15–0.35 mm, with specific thickness adjusted based on the equipment’s operating frequency and rated voltage.

Q: How does laminate coating affect equipment performance?

A: The coating’s primary function is to ensure insulation between laminations, preventing short circuits while maintaining the magnetic core’s integrity for stable operation.

Q: Are laminated cores more cost-effective than solid cores?

A: While laminated cores have higher upfront manufacturing costs, their significant energy-saving benefits and reduced thermal wear over extended use make them the more economical choice in most applications.