Perché i lamierini del nucleo EI sono fondamentali per trasformatori efficienti

Introduction: Why Does EI Core Lamination Hold Such an Indispensable Position?

When evaluating high-performance transformers, EI laminated core technology stands as a foundational concept that cannot be overlooked. Whether reducing energy consumption or enhancing magnetic permeability, manufacturers like ours regard EI laminated core technology as a core competitive advantage. This article delves into EI laminated core technology, explaining why it plays a crucial role in transformer design and performance.

1. Understanding EI Core Lamination: The Foundation of Magnetic Efficiency

Contenuti

- 1 1. Understanding EI Core Lamination: The Foundation of Magnetic Efficiency

- 2 2. Achieving Energy Savings Through EI Core Lamination

- 3 3. Manufacturing Precision: The Key to Enhancing EI Core Laminate Quality

- 4 4. Customization Advantages of EI Core Laminates

- 5 5. Impact of Material Selection on EI Core Laminations

- 6 6. Outstanding Noise Reduction Advantages of EI Laminated Cores

- 7 7. Correlation Between Thermal Management and Transformer Lifespan

- 8 8. Wide Application Range: Spanning Industrial and Consumer Sectors

- 9 9. Environmental Impact: Efficient EI Core Laminations Support Sustainability

- 10 10. Innovative Advancements in EI Core Lamination Technology

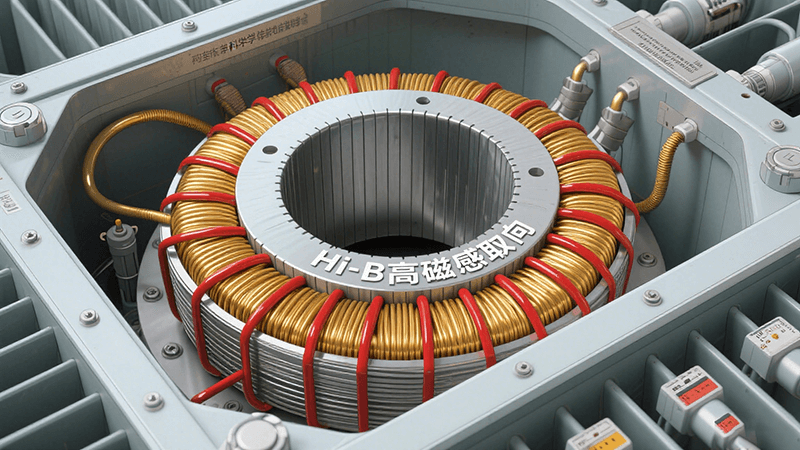

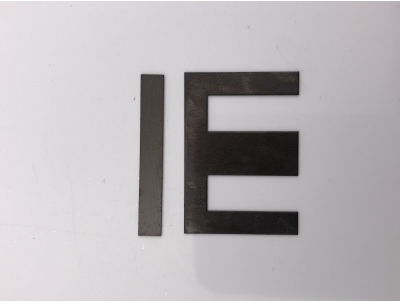

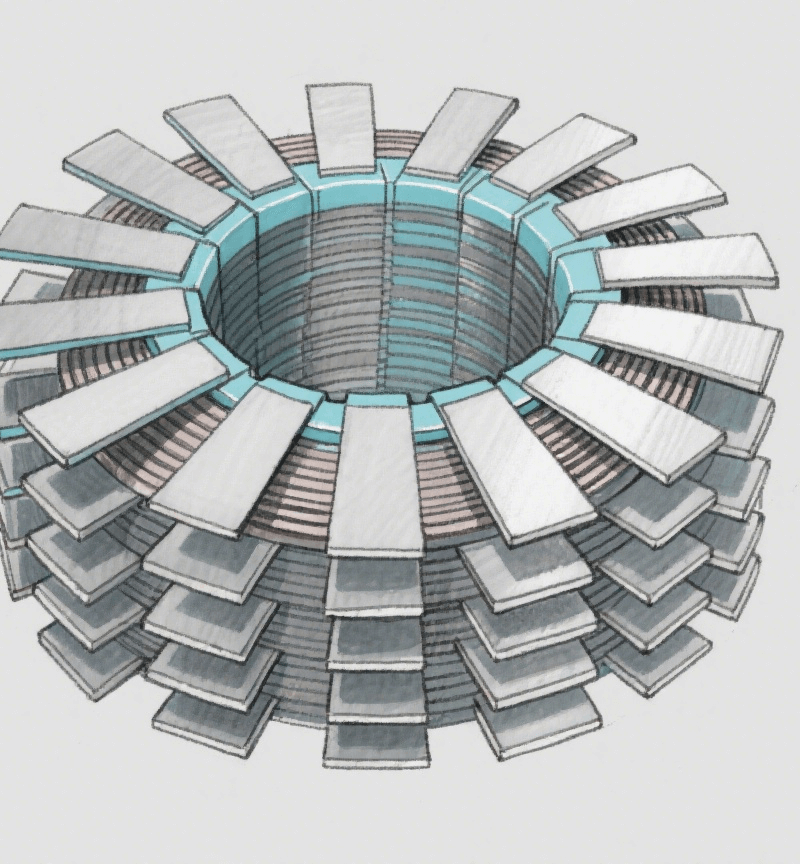

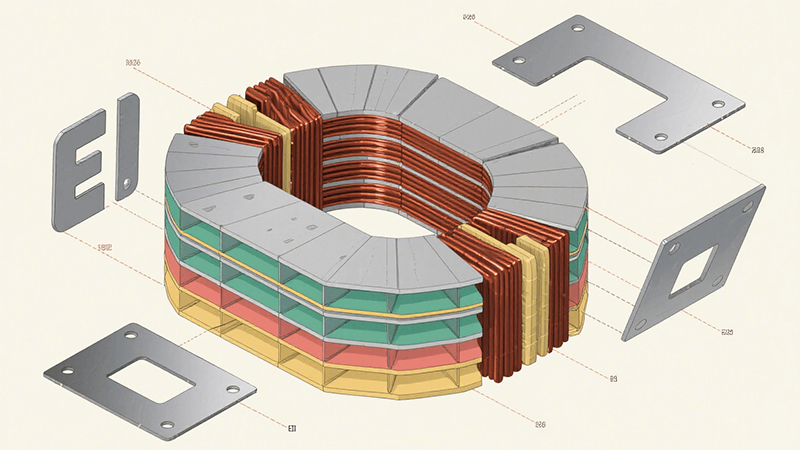

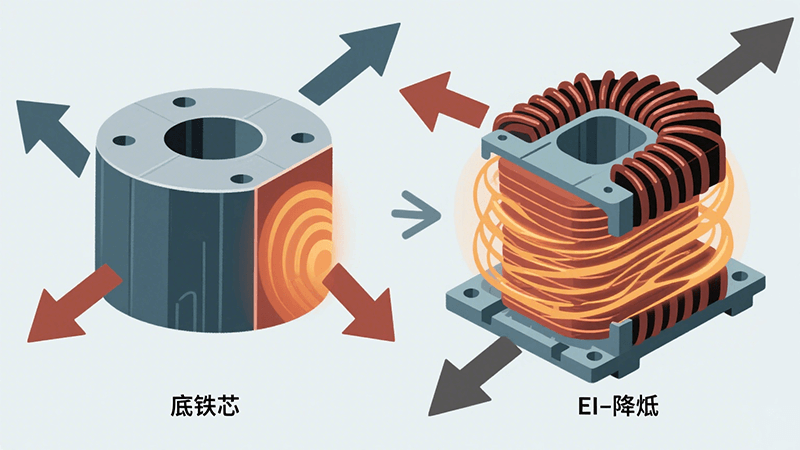

The essence of EI core lamination lies in stacking thin, insulated electrical steel sheets (typically E-shaped or I-shaped) to form the internal magnetic circuit of a transformer. Compared to solid cores, this technology significantly reduces eddy current losses because the insulation between layers effectively blocks circulating currents. Leveraging this engineering principle, we enhance transformer operational efficiency, resulting in products that generate less heat and achieve higher energy utilization.

2. Achieving Energy Savings Through EI Core Lamination

Energy efficiency remains a core focus in the electrical appliance industry. Scientifically optimized Laminazioni del nucleo EI minimize eddy current and hysteresis losses, reducing unnecessary energy waste. This ensures our transformers maintain low operating temperatures during prolonged use, guaranteeing stable performance while delivering dual savings in energy consumption and operational costs.

3. Manufacturing Precision: The Key to Enhancing EI Core Laminate Quality

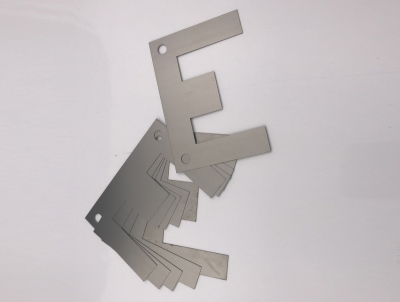

For EI core laminates, precise trimming and stacking operations are essential to meet stringent tolerance requirements. Misalignment or poor-quality laminates can increase transformer noise, intensify vibration, and potentially cause hotspot issues. Our company employs advanced CNC punching technology and automated assembly equipment to guarantee uniform stacking and precise alignment for every EI laminate, providing robust support for transformers to deliver outstanding performance.

4. Customization Advantages of EI Core Laminates

Whether you produce small low-voltage transformers or large industrial-grade units, EI laminates offer exceptional customization flexibility. We offer diverse customization options—from laminate thickness specifications to insulation material selection—tailored to your specific requirements, delivering bespoke transformer solutions. Our engineers can adjust various laminate parameters to achieve targeted frequency response characteristics, magnetic performance metrics, and physical dimensional specifications.

5. Impact of Material Selection on EI Core Laminations

The magnetic properties of the steel used in EI core laminations play a pivotal role. High-quality electrical steel with low carbon content and grain orientation optimization effectively enhances magnetic permeability while reducing core losses. Our production process rigorously selects premium raw materials, ensuring every EI laminated core meets stringent performance standards.

6. Outstanding Noise Reduction Advantages of EI Laminated Cores

The humming sounds and vibrations generated during transformer operation not only cause interference but can sometimes signal equipment malfunctions. Through meticulous design of EI core laminations—such as employing tight stacking methods and scientific clamping techniques—engineers can significantly reduce operational noise. Our production process fully incorporates these mechanical design principles to ensure quieter transformer operation.

7. Correlation Between Thermal Management and Transformer Lifespan

Efficient heat dissipation is a key factor in extending transformer lifespan. EI laminated cores not only reduce heat generation but also create effective cooling channels between laminations, enhancing the transformer’s thermal performance. Our transformers utilize optimally designed EI laminated cores, delivering superior thermal characteristics that typically result in longer service life and higher operational reliability.

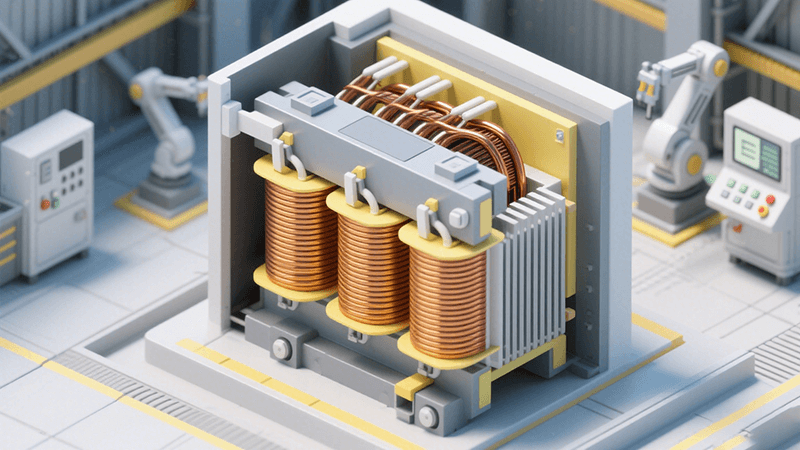

8. Wide Applicazione Range: Spanning Industrial and Consumer Sectors

EI laminated core technology demonstrates remarkable adaptability across diverse applications, serving both industrial power transformers and compact consumer appliance transformers. Our company fully leverages this technology’s versatility, integrating EI laminated cores into various product lines to meet distinct performance and dimensional requirements while serving diverse markets.

9. Environmental Impact: Efficient EI Core Laminations Support Sustainability

As sustainable development principles gain widespread adoption, the efficient EI core laminated technology helps reduce energy waste and lower greenhouse gas emissions. Transformers manufactured using high-performance laminations (such as those produced by our company) enable enterprises to adopt more environmentally friendly operational models, aligning with global energy efficiency standards and eco-design regulations.

10. Innovative Advancements in EI Core Lamination Technology

Continuous innovation drives the refinement of EI core lamination technology—from developing thinner laminations and adopting advanced insulation coating techniques to upgrading automated assembly processes. Our company remains at the forefront of industry development, increasing R&D investment to push the boundaries of transformer performance through ongoing improvements to EI core lamination technology.

Conclusion: The Significance of EI Core Lamination

Within transformer construction, EI core lamination transcends mere manufacturing detail—it is a critical determinant of transformer performance. It profoundly influences energy efficiency, operational noise, thermal behavior, service life, and environmental impact. Companies like ours recognize that investing resources to enhance lamination quality serves not only engineering design requirements but also delivers reliable, energy-efficient solutions to the market.

Should you wish to learn more about how we apply EI core laminations in practical design work, please feel free to contact me! I would be delighted to engage in further discussions regarding transformer case studies or share professional insights within the manufacturing sector.